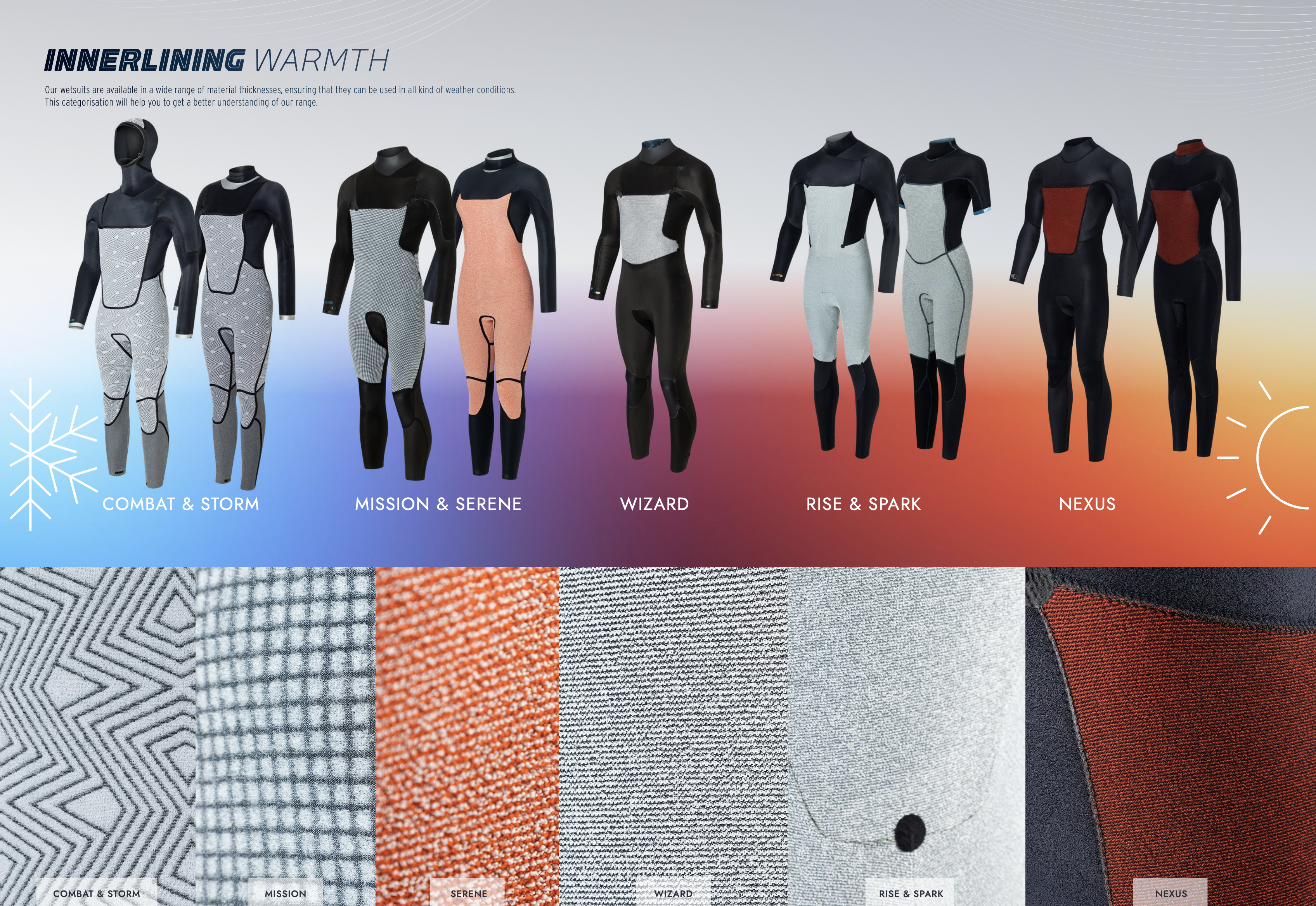

TRIPLE LAMINATED TECHNOLOGY

HIGH FLEX MATERIAL

How is a wetsuit constructed and what makes NeilPryde's selection of materials extra flexible?

LAYER 1

OUTER LINING

As the outermost layer, the outer lining is exposed directly to the elements. UV-resistance, abrasion resistance and the ability to repel water play an important role. As the outer liner is directly bonded to the actual neoprene, the flex and stretch behavior of this layer also influences the flex of the entire suit.

For us wind-dependent water sports enthusiasts, the thermal performance of the suit also depends largely on the ability of the material to repel or absorb water (wind chill effect).

Last but not least, this is of course also the most visible layer and in addition to the "performance factors", look and feel play an important role in choosing the right material.

LAYER 2

NEOPRENE

In simple terms, the actual neoprene material is a type of rubber compound that is foamed and "baked" during the manufacturing process. Millions of tiny gas bubbles introduced into the material during the foaming process have a decisive influence on the thermal insulation characteristics and the hardness or softness (flex) of the material.

A number of different quality levels are distinguished, with the higher qualities representing an ever-improving combination of durability, warmth and flexibility.

At NeilPryde, we only choose between the two highest quality levels, depending on the requirements, and for the last two years have also been equipping the suits in our more affordable price categories (e.g. Rise) with these very high-quality and expensive neoprene materials (e.g. Yamamoto #40, Sheico Limestone).

LAYER 3

INNER LINING

In addition to its function as a protective shield for the more sensitive neoprene, the inner lining primarily fulfills the requirements for thermal insulation.

Thicker, fluffier linings store air and water in the suit, which are warmed by the body, keeping the temperature comfortable and increasing insulation. However, they often have the disadvantage of being less flexible.

In general, there are three different types of thermal inner lamination, each of which has different quality levels. This means that even if it is visually almost indistinguishable, an inner lamination can be very flexible or very stiff.

At NeilPryde, we have been using only the highest quality (and flex) level for 2 years. This makes our Rise suits, for example, probably the most flexible suits on the market in this price category, despite continuous thermal lamination from the chest to the knees.

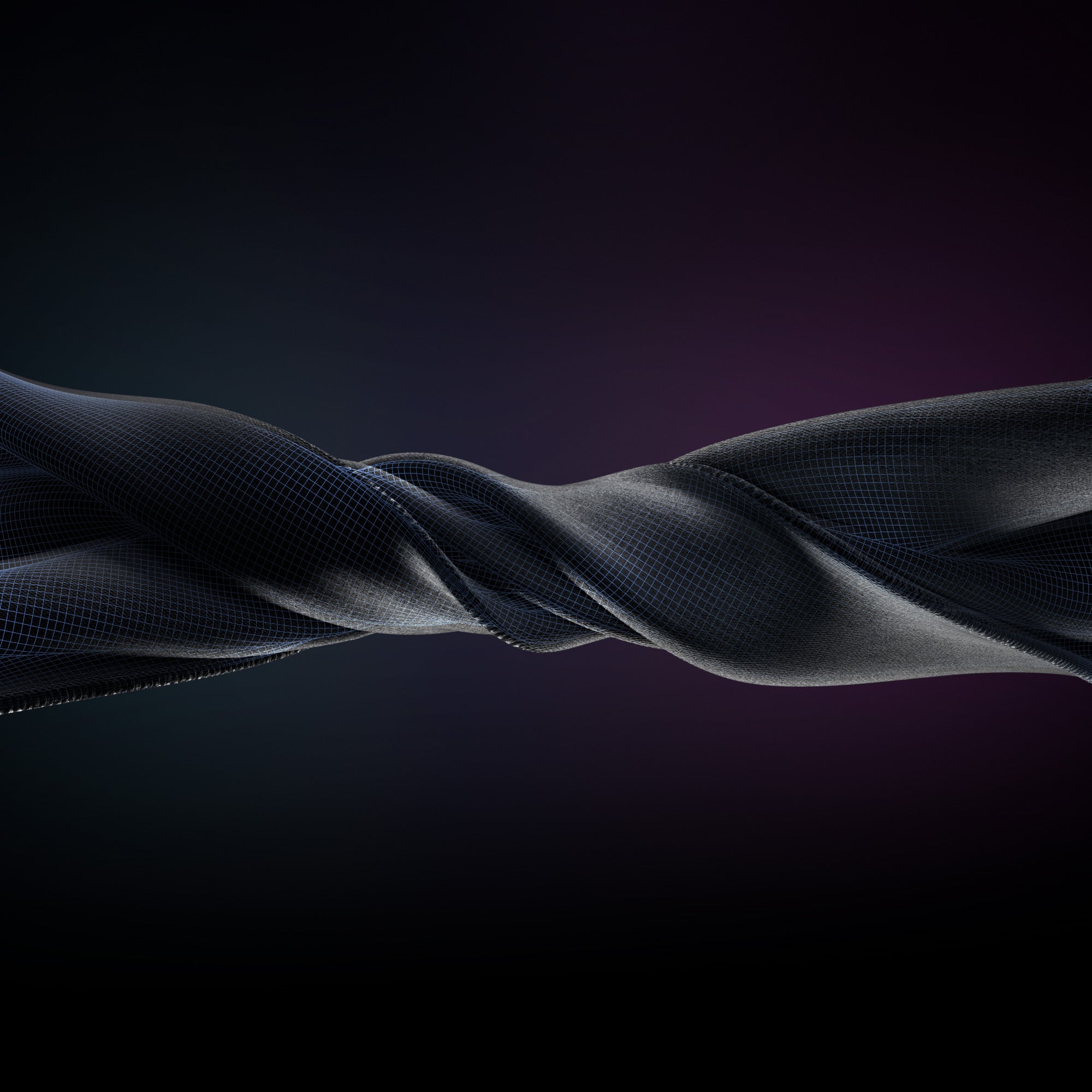

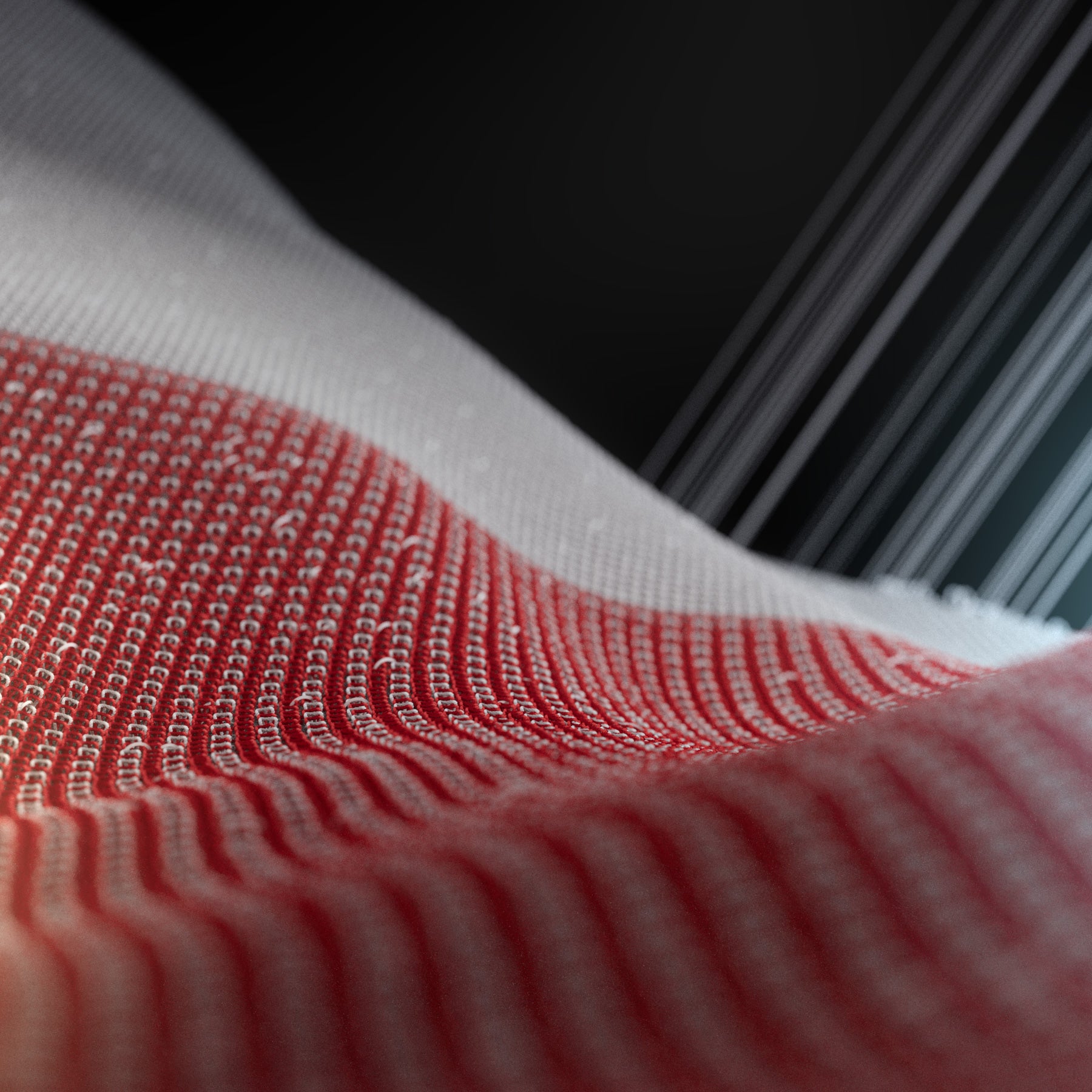

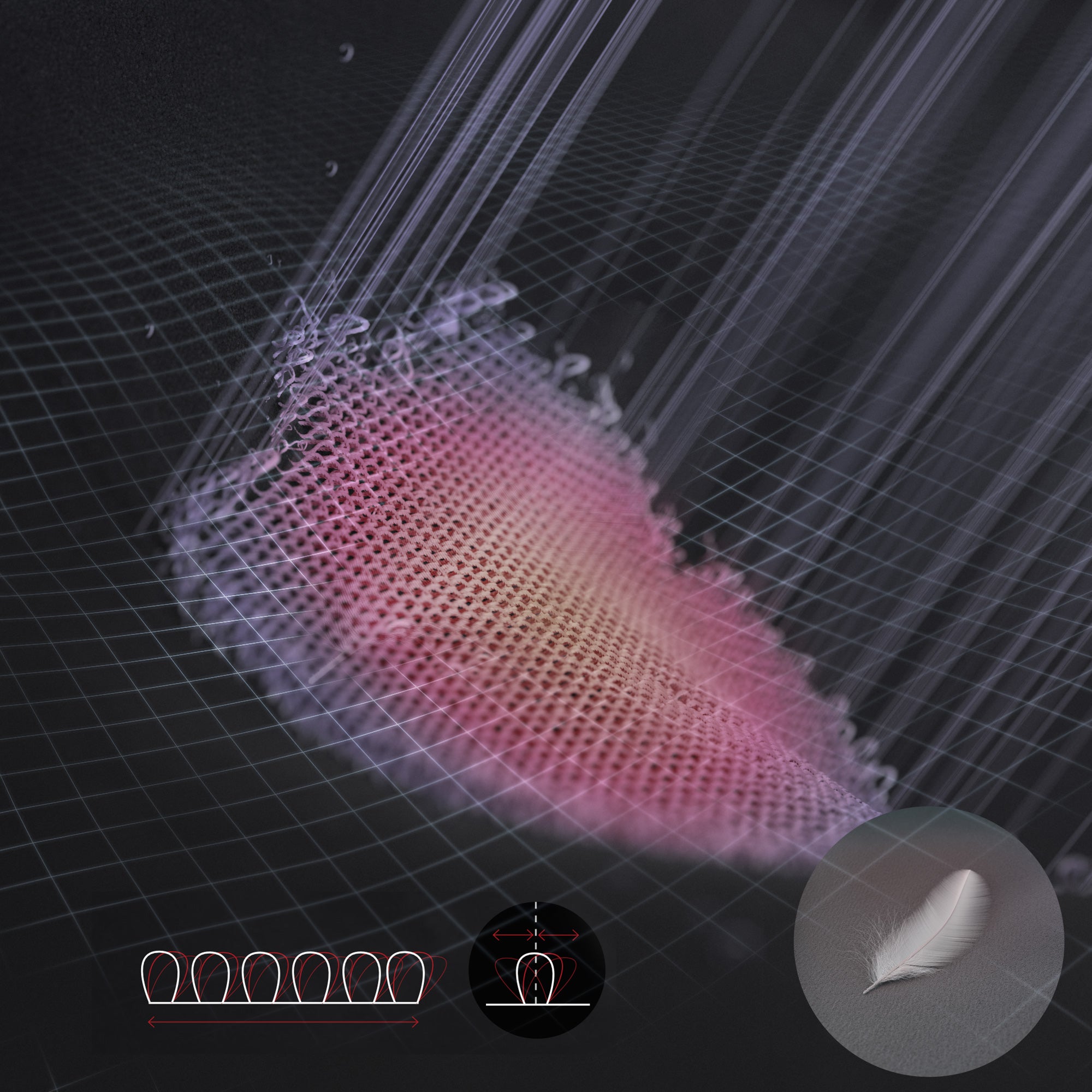

FIRELINE PRO & LIGHT

The innovative NeilPryde Innerlinings Fireline Pro and Fireline Light stand out for their looped construction, where the loops are not interconnected. This unique design ensures that the material doesn‘t hinder flexibility by avoiding mutual blockage during stretching.

The result is a comfortable flex that enhances the overall performance and comfort of the product. NeilPryde‘s commitment to advanced materials and thoughtful design shines through, providing users with a cutting-edge experience that optimizes freedom of movement and comfort during use.

Available in Wizard, Rise & Spark